Density Meter | Digital Hydrometer

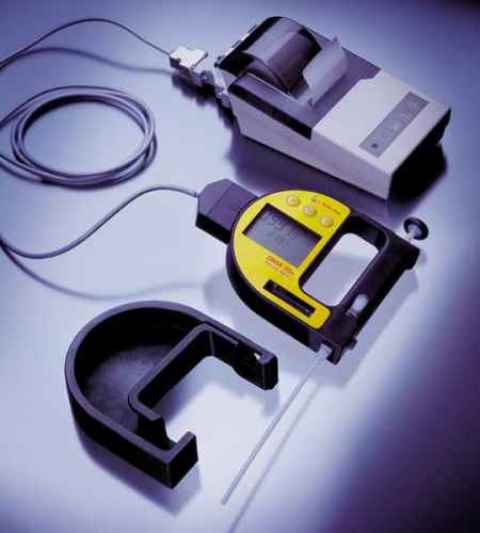

The portable density meter is ideal for beginners. It measures sample density directly and easily on-site. Using the built-in pump, the device draws samples from the storage container and instantly displays the results—either as density or as concentration in units like °Brix, %v/v alcohol, or %w/w H₂SO₄ (sulfuric acid). Thanks to its lightweight and compact design, the measuring device is also suitable for hard-to-reach samples, such as batteries in tight shelves or wine samples from stacked barrels.

Technical Highlights of the Density Meter Compared to the Glass Hydrometer

- Minimal Sample Volume: Only 2 ml of sample is needed, helping to avoid sample waste.

- Direct Sample Collection On-Site: The built-in pump draws samples directly from the container, simplifying the process.

- Integrated Conversion Table: Results are displayed directly in preferred units, eliminating the need for extra calculations.

- Wide Measurement Range: This device can replace a full set of hydrometers.

- Automatic Temperature Compensation: Results are precise and reliable within seconds.

- Efficient Data Management and Easy Transfer: Stored results can be automatically transferred, eliminating manual note-taking.

- Consistent Results: The results are reliable and consistent, regardless of user experience.

- Lightweight and Robust Design: This allows for easy transport and safe storage.

This device is the lightest of its kind on the market. Its slim design allows it to fit into narrow spaces, such as wine cellars or battery production facilities. A protective case, rubber housing, and shoulder strap make the device ideal for safe on-site use. It is leakproof (IP54) and reliably resists sample splashes. The chemical resistance of sample-contacting parts has been thoroughly tested, protecting the device from the effects of solutions and acids for a long-lasting lifespan.

Smart Features for an Optimized Workflow

The device includes a backlit display and an illuminated measuring cell, making it easy to use even in dark environments. Sample IDs can be saved and assigned to sampling locations. Stored results can be conveniently printed or exported via the IrDA interface, enabling quick and efficient data processing.

We are happy to advise you on topics related to: Lead Batteries | Battery cells | Battery testing